FAQ

Chuo Yii's Technical Insights

Chuo Yii is pleased to share expertise in precision Aluminum foundry & machining, and air rings of blown film. With years of experience assisting customers and providing tailored solutions, we help technicians and professional buyers troubleshoot common challenges efficiently. Explore our technical insights or contact our sales representatives for expert guidance and practical solutions.

Blow-Up Ratio (B.U.R.) is the ratio of the final blown film diameter to the die lip diameter, affecting film thickness and strength. For LDPE/LLDPE, B.U.R. is typically 2 to 3, while for HDPE, it ranges...

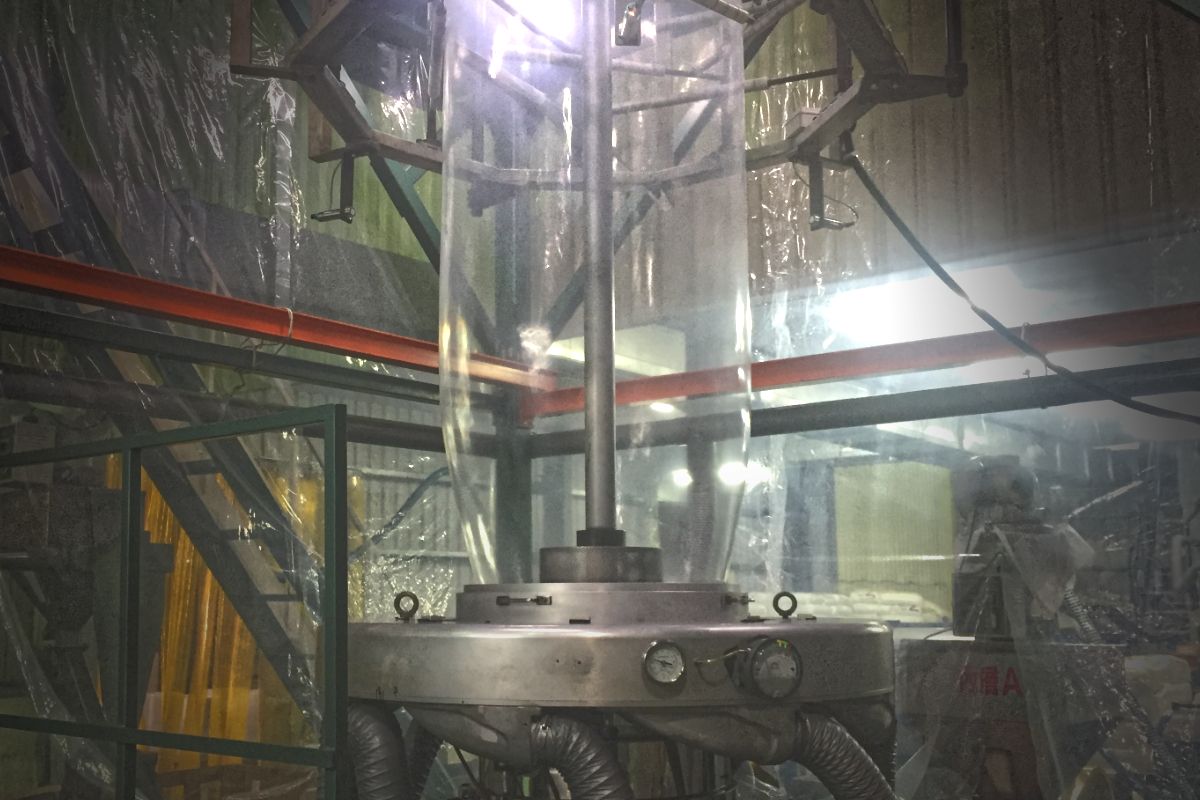

Read moreUnstable bubble blowing can be caused by various factors, including cooling air, environmental airflow, and B.U.R. Here are the common checks and solutions:Air Ring Exit Position: Check if the air ring...

Read moreThickness or gauge variation can result from issues with the air ring, die head, material feeding, or B.U.R. Here are common checks and actions:Incorrect Coupling Between Air Ring and Die Head: Ensure...

Read moreThe optical properties of blown film are influenced by the material type, temperature, and die gap size. Here are common checks and solutions:Frost Line Too High: Lower the height of the frost line to improve...

Read moreBlown film productivity is mainly influenced by the die head, extruder, and cooling effect. Here are common checks and actions:Too High Pressure of Die Head? Check for screen changer blockage. Consider...

Read moreMelt fracture, also known as sharkskin or surface melt fracture, often occurs at the die head and material stage. Here are common checks and solutions:Die Gap Too Narrow? Replace with larger gap die inserts...

Read moreBlocking bubbles occur when the opposite faces of the film stick or adhere to each other. Here are common checks and solutions:Insufficient Bubble Cooling? Increase the cooling air supply to prevent...

Read moreSealing quality is influenced by sealing dwelling time, temperature, blade clamping pressure, and cooling conditions. Here are common checks and solutions:High Film Thickness Variation or Incorrect Gauge? Refer...

Read moreDie lip build-up or die line can occur when the die head or molten temperature is too high. Here are common checks and solutions:Die Head Temperature Too High? Decrease the die head temperature to avoid...

Read moreExtruder feeding and temperature settings are critical for optimal performance. Here are common checks and solutions:Improper Extruder Temperature Setting? Readjust and properly set the extruder temperatures...

Read more