Poor optical film

The optical properties of blown film are influenced by the material type, temperature, and die gap size. Here are common checks and solutions:

Frost Line Too High:

Lower the height of the frost line to improve optical clarity.

Molten Temperature Too Low:

Increase the temperature of the extruder and die head to optimize melt flow and transparency.

Melt Fracture:

Refer to the Solution of Melt Fracture for further guidance on fixing melt issues.

Too Wide Die Gap:

Replace the die pins with narrower ones to improve film thickness and optical consistency.

Formulation or Additive Issues:

Excessive anti-block agent or improper additives can affect film quality. Use higher-flow index and lower-density polymer, and optimize additive levels for better results.

- Related Products

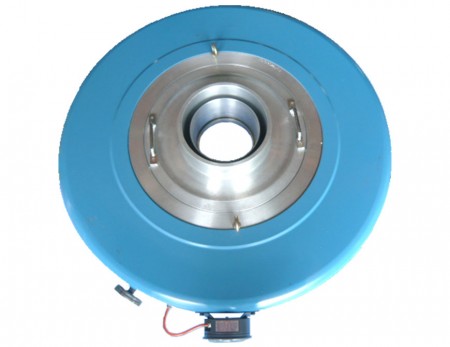

Fast Cooling Dual Lips Air ring

AREO-2

Super fast air ring for thick film, packaging film, low variation film thickness requirement...

DetailsLow Variation Dual Lips Air ring

AREO-1

Super fast air ring for thin film, packaging film, low variation film thickness requirement,...

DetailsHDPE High Speed Dual Lips Air ring

AREO-5

Super high speed HDPE air ring, AREO-5 is applied for thin or thick, single or multi-layer...

Details- Files Download