Suitable Blow-up ratio

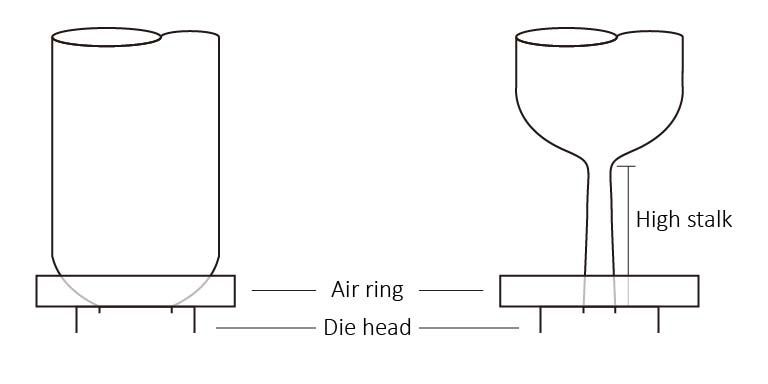

Blow-Up Ratio (B.U.R.) is the ratio of the final blown film diameter to the die lip diameter, affecting film thickness and strength. For LDPE/LLDPE, B.U.R. is typically 2 to 3, while for HDPE, it ranges from 6 to 8.

To calculate B.U.R., use this formula:

(Lay Flat Film Width × 2) ÷ (3.1416 × Die Lip Size)

Optimizing the B.U.R. is crucial for improving the overall quality of blown film production. By fine-tuning the B.U.R., manufacturers can achieve enhanced film flexibility, making it more resistant to tearing and improving its processing capabilities. An optimal B.U.R. also improves transparency, resulting in clearer, higher-quality films that are ideal for packaging and other applications requiring aesthetic appeal. Furthermore, optimizing B.U.R. ensures consistent film thickness, reducing defects and waste, which directly impacts cost-effectiveness. This ratio is directly tied to the cooling and stretching process of the film, affecting its mechanical properties. By maintaining the proper B.U.R., producers can enhance the film’s dimensional stability and performance, resulting in superior product quality with fewer production issues. Overall, careful management of the B.U.R. not only boosts film performance but also leads to more efficient production, better end-product consistency, and reduced material usage.

- Related Products

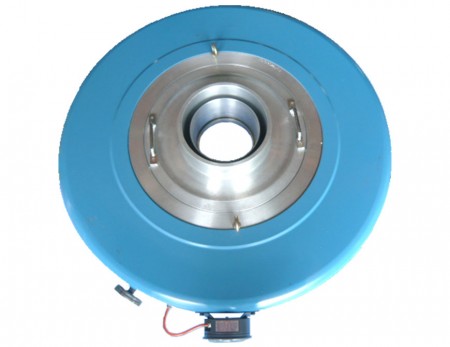

Low Variation Dual Lips Air ring

AREO-1

Super fast air ring for thin film, packaging film, low variation film thickness requirement,...

DetailsHDPE High Speed Dual Lips Air ring

AREO-5

Super high speed HDPE air ring, AREO-5 is applied for thin or thick, single or multi-layer...

Details- Files Download