Company Profile

Air rings & Die heads - Blown film Extrusion

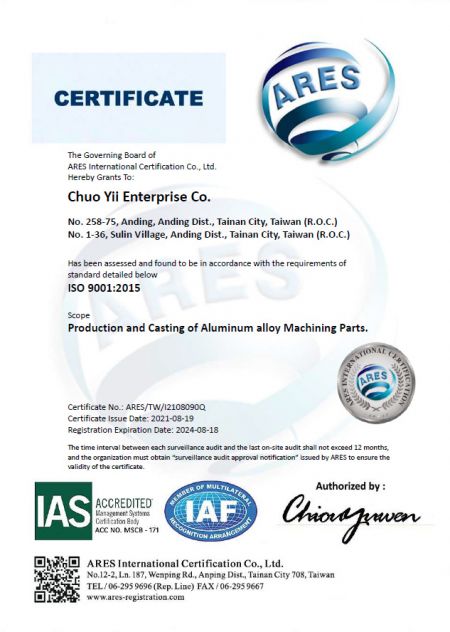

During the past 40 years, Blown Film Extrusion Machines from Taiwan have taken a big share of global market; CHUO YII Enterprise Co. has joined to this market 25 years ago. Nowadays, she works for more than 45 countries in the world by exporting the excellent products, the main core of blown film machinery - Air ring and Die head.

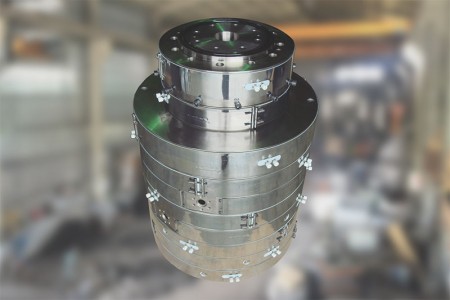

Owing to the excellent Venturi effect Air ring and Die head, and from mono layer blown film to multi-layer film; Shopping bag film, barrier film, to lamination film, CHUO YII provides a wide range of Air rings and Die heads optionally.

Machine assemblers know their way of solution to various air blown problems since they count on CHUO YII and rely on CHUO YII's techniques.

Owing to the self-owned Aluminum alloy sand casting foundry, and the sound CNC machining center, she works strongly in the field of plastic blown film extrusion industries. Except CHUO YII Air ring and Die head or the related accessories, she also works for OEM Aluminum foundry items for marine, robot parts or industrial parts.

Air rings and Die heads expert

CHUO YII Enterprise Co. owns aluminum alloy sand casting foundry, and CNC machining center; and has been in the field of plastic blown film machineries parts more than 25 years. OEM/ODM works also includes: Air Ring, Die Head and huge size Aluminum Sand Casting objects. All are made in its own house; each process of working is under very strict process control, so that to ensure the products are always kept high level and outstanding performance. CY air rings and die heads are working properly under maximum output capacity, lowest gauge variation (low film thickness variation), bubble stability, glossy, neat film rolled up as well as durable and long life purposes. All sorts of blown films such as HDPE / LDPE / LLDPE / MDPE / PP / PVC / PA / PLA, mono / multi-layer up to 7 layers are included in our production filed.

ECO Mulch Film Total Solution

In September 2024, CHUO YII Enterprise Co. launched a dedicated department focused on promoting ECO-friendly agricultural practices. The initiative centers around two key products:

1. Oxo-Biodegradable Additives (Masterbatch) / SCM-3611 – For Mulch Film production

2. Microbial Fertilizer / SZY – Designed for application in mulch film-covered lands

The CY ECO Mulch Film Solution integrates innovative technologies, including CY Air Ring and Die Head systems, oxo-biodegradable additives (SCM-3611), and Microbial Fertilizer (SZY), to create a comprehensive, sustainable approach to agriculture.

With this solution, mulch films made using oxo-biodegradable additives naturally decompose, leaving no harmful residues and eliminating labor-intensive removal processes. The solution also supports every stage of farming, from expert consultation to application guidance, ensuring optimal soil health and crop growth. By reducing water evaporation, retaining moisture, and controlling weeds, CY's solution enhances productivity while safeguarding the environment.

Through workshops and partnerships, CY actively promotes sustainable farming practices. By adopting CY ECO Mulch Film, farmers can achieve higher yields and contribute to a greener, more sustainable future for agriculture.

History Records

- 1997: CHUO YII Industries was established and acted as mainly machining shop for air ring and all sorts of machining parts.

- 2009: Upgrade the company scale as CHUO YII Enterprise Co. and at the same time inviting Aluminum foundry facilities and brought in vertical CNC machine for air ring processing of all sorts and sizes; as well as die head or other accessories processing.

- 2010: Established the 2nd factory located at the Anding Industrial Area, Tainan, where mainly working for aluminum foundry and accepts all sorts of OEM / ODM sand casting works.

- 2024: Established a new department focused on delivering a comprehensive ECO Mulch Film Total Solution. This solution encompasses three key components: Mulch Film Air Ring and Die Head technology, oxo-biodegradable additives, and organic fertilizers.

High output, Stable bubble and Low variation of film thickness.

- Highly stable and high output air ring.

- Alum sand casting foundry works.

- For thick film with fast cooling and stable effect - Adjustable exits.

- From material to finishing products 100% MADE IN OWN HOUSE.

- High speed HDPE blown film air ring.

- Top level high technology ensure the maximum production and stability.

- Die head and accessory of Rotary Device.

- Introduction video